+91 9820814560

High-performance alloy Incoloy 330 is renowned for its remarkable ability to withstand oxidation and carburization at high temperatures. This nickel-chromium-iron alloy's strength and resistance to corrosion under abrasive conditions make it very valuable in high-temperature industrial applications. About 34–37% of the alloy's composition is chromium, and the remaining 20–60% is carbon, with nickel making up the majority. Because of its composition, Incoloy 330 is more resistant to oxidation and carburization, which makes it appropriate for use in settings with temperatures above 1000°C (1830°F). While the nickel helps improve its resistance to carburization and lowers the risk of embrittlement, the high chromium concentration increases its resistance to oxidation.

Applications for Incoloy 330 are numerous and include furnace parts, combustion chambers, and heat exchangers. It works especially well in settings with sulfur and carbon, like petrochemical manufacturing facilities or coal-fired power stations. Because of the alloy's strength at high temperatures, it can function consistently in use without experiencing appreciable degradation.

The capacity of Incoloy 330 to withstand thermal cycling is one of its main advantages since it enables components exposed to temperature fluctuations last longer. It also exhibits good weldability and machinability, which streamlines the fabrication and assembly procedures.

Pipe Specification : ASTM B535, B710 / ASME SB535, SB710

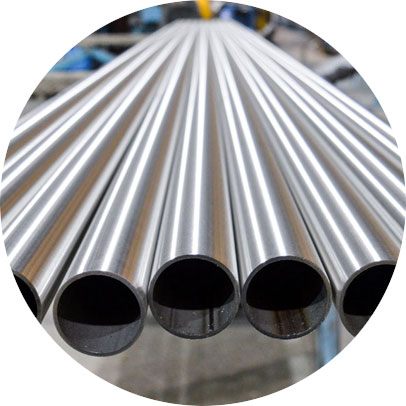

Seamless Pipes : 1/4" NB To 6" NB

Welded Pipes : 1" NB To 16" NB

Schedule : SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

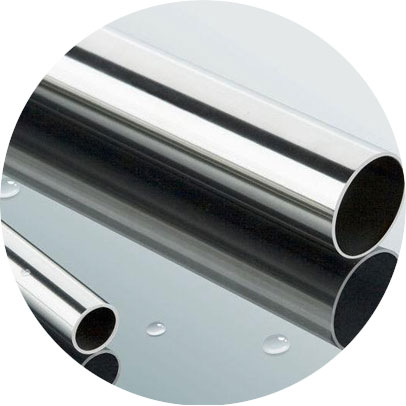

Type : Seamless Pipe, Welded Pipe, ERW Pipe, Fabricated Pipe, CDW

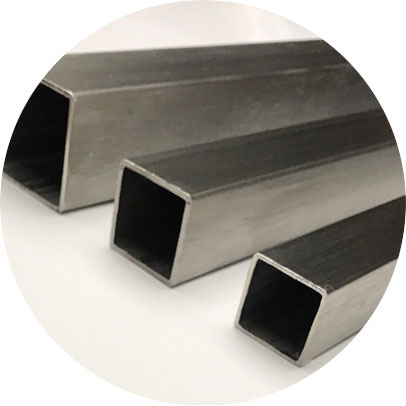

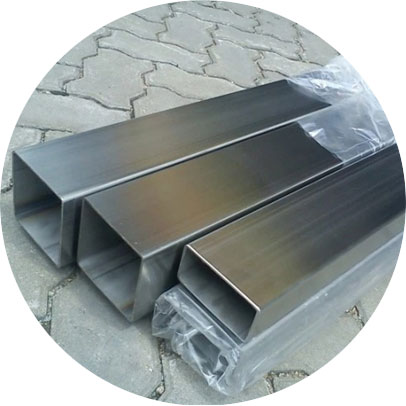

Form : Round Pipes, Square Pipes, Rectangular Pipe

Length : Single Random, Double Random & Cut Length.

End : Plain End, Beveled End, Threaded

End Protection : Plastic Caps

Outside Finish : 2B, No.1, No.4, No.8 Mirror Finish

Finish : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

External Coating : 3LPE / 3LPP/ FBE/ DFBE/ PP

Origin : Indian Origin, European Origin, Japanese Origin

Testing and Documents : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports

Packing : Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests

A Wide Range of ASTM B535 / B710 Incoloy 330 Pipes at Best Price.

Call : +91-9820814560 or Send Enquiry

Incoloy 330 Seamless Pipe

Incoloy 330 Welded Pipe

Incoloy 330 ERW Pipe

Incoloy 330 Pipe

Alloy 330 Pipe

Incoloy 330 Square Pipe

Incoloy 330 Rectangular Pipe

Incoloy 330 Round Pipe

| STANDARD | WERKSTOFF NR. | UNS | JIS |

| Incoloy 330 | 1.4886 | N08330 | NCF 330 |

| GRADE | C | MN | P | S | Si | Cr | Ni | Mo | Cu | Fe | Sn | Pb |

| Incoloy 330 | 0.08 max | 2.00 max | 0.03 max | 0.03 max | 0.75-1.50 | 17.0-20.0 | 34.0-37.0 | 1.0-1.75 | 1.00 max | Balance | 0.025 | 0.005 max |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Incoloy 330 | 8.08 g/cm3 | 1380 °C (2520 °F) | 600 MPa | 280 MPa | 45 % |

Incoloy 330 Pipes

Incoloy 330 Seamless Pipe

Incoloy® Alloy 330 Pipe

ASTM B535 Incoloy 330 Seamless Pipe

330 Incoloy Welded Pipes

Incoloy 330 ERW Pipes

Alloy 330 Pipes Stockist

Incoloy 330 Rectangular Pipes Supplier

ASME SB535 330 Incoloy Round Pipes

Incoloy JIS NCF 330 Pipes

Incoloy® 330 Square Pipe Exporter

Nickel Alloy N08330 Pipe

Incoloy UNS 330 Hydraulic Pipes

Incoloy 1.4886 Pipes

Alloy 330 Pipe

Incoloy UNS N08330 Pipes

Incoloy Alloy 330 Welded Pipes

Incoloy® Alloy 330 Pipe

ASTM B535 Incoloy 330 Seamless Pipe

330 Incoloy Electropolish Pipe

Nickel Alloy 330 Thick Wall Pipe

330 Incoloy Seamless Pipe

High Quality Incoloy 330 Pipe

Nickel Alloy 330 ERW Pipe

Alloy 330 Square Pipe

Incoloy JIS NCF 330 Pipe

Incoloy 330 Rectangular Pipe

ASME SB710 Incoloy® Alloy 330 ERW Pipe

Large Selection of Incoloy 330 Pipe

330 Incoloy Seamless Piping

Incoloy® Alloy 330 Pipe Distributor

Incoloy 330 Cold Drawn Seamless Pipe

ASTM B710 330 Incoloy Pipe

Incoloy UNS N08330 Pipes

Incoloy DIN 1.4886 Seamless Pipes

330 Incoloy Hexagonal Pipe

Incoloy 330 Hallow Pipe Manufacturer

Nickel Alloy 330 Bush Hex Pipe Dealer

Incoloy® Alloy 330 Flexible Hose Pipe

Incoloy Alloy 330 Pipe

Incoloy 330 Capillary Pipe

Alloy 330 Electropolished Pipes

We have regular exports of Incoloy 330 Pipes in Europe, Kuwait, Bangladesh, UAE, Hong Kong, Poland, Bahrain, Jordan, Nepal, United States, Algeria, Yemen, Spain, Qatar, Ghana, Malaysia, Philippines, United Kingdom, Chile, Azerbaijan, Lithuania, Saudi Arabia, Iran, Trinidad & Tobago,Tunisia, Turkey, Brazil, Iran, Poland, Japan, France, USA, Belgium, Thailand, Estonia, Brazil, Vietnam, China, Chile, Costa Rica, Iran, Japan, Malaysia, Congo, Germany, Egypt, Tibet, United Arab Emirates, South Africa, South Korea, Ireland, Finland, Italy, Taiwan, Sweden, Czech Republic, Iraq, Puerto Rico, Austria, Ukraine, Mexico, Pakistan, Portugal, Netherlands, Denmark, Sri Lanka, Gabon, Kazakhstan, Bulgaria, Angola, Bhutan, Romania, Indonesia, Ecuador, Canada, Nigeria, Singapore, Argentina, Israel, Venezuela, Nigeria, Afghanistan, Bolivia, Peru, Russia, Switzerland, Libya, Kenya, Macau, New Zealand, Lebanon, Belarus, Mongolia, Croatia, Gambia, Morocco, Slovakia, Australia, Colombia, Norway, Oman, Hungary, Mexico, India, Zimbabwe, Namibia, Serbia, Greece.

We are Leading Supplier of ASTM B535 330 Incoloy Pipe in Mumbai, Maharashtra, Gujarat, Jamshedpur, Pune, Thiruvanthapuram, Jaipur, Lucknow, Coimbatore, Imphal, Mysore, Ratlam, Delhi, Kanpur, Darjeeling, Jalandhar, Nagpur, Solapur, Kolkata, Allahabad, Dehradun, Jammu, Nashik, Srinagar, Chennai, Ahmedabad, Faridabad, Bhadravati, Chattisgarh, Durgapur, Asansol, Hospet, Bellary, Visakhapatnam, Nellore, Surat, Bangalore, Chandigarh, Ghaziabad, Jhansi, Patna, Siliguri, Hyderabad, Amritsar, Noida, Kochi, Aizawl, Guwahati, Kozhikode, Raipur, Vishakhapatnam, Jabalpur, Bhopal, Gwalior, Ludhiana, Rajahmundry, Thane, Agra, Bhubaneshwar, Gurgaon, Madurai, Rajkot, Varanasi, Bhilai, Haridwar, Meerut, Ranchi, Ahmednagar, Akola, Amravati, Aurangabad, Baramati, Beed, Bhandara, Bhiwandi, Buldhana, Chandrapur, Chimur, Dahanu, Dhule, Dindori, Erandol, Gadchiroli, Hatkanangle, Hingoli, Ichalkaranji, Jalgaon, Jalna, Karad, Khed, Yavatmal, Kolaba, Kolhapur, Kopargaon, Latur, Malegaon, Mumbai, Nagpur, Nanded, Nandurbar, Nashik, Osmanabad, Pandharpur, Parbhani, Rajapur, Ramtek, Ratnagiri, Raver, Sangli, Satara, Shirdi, Shirur, Solapur, Thane, Wardha, Washim, Andhra Pradesh, Jammu and Kashmir, Nagaland, Uttarakhand, Haryana, Lakshadweep, Arunachal Pradesh, Jharkhand, Odisha, West Bengal, Himachal Pradesh, Assam, Karnataka, Punjab, Andaman and Nicobar Islands, Puducherry, Bihar, Kerala, Rajasthan, Chandigarh, Meghalaya, Chhattisgarh, Madhya Pradesh, Sikkim, Dadar and Nagar Haveli, Mizoram, Goa, Tamil Nadu, Daman and Diu, Tripura, Manipur, Telangana, Delhi, Uttar Pradesh in India.