+91 9820814560

A high-performance material with unique qualities and versatility, nickel alloy 201 is widely utilized in the fabrication of pipe fittings. Alloy 201, which is mostly composed of nickel (around 99%), with trace amounts of silicon and manganese, is renowned for having a high level of resistance to oxidation and corrosion. Because of this, it is the best option for settings where exposure to harsh materials like acids, alkaline solutions, and high-temperature gases is possible. The exceptional resistance of Nickel Alloy 201 against stress-corrosion cracking and pitting, among other types of corrosion, is one of its distinguishing characteristics. Because of this, it is especially well-suited for uses in extreme environments like chemical processing, aerospace, and maritime environments. Furthermore, the alloy remains strong and ductile at high temperatures, which is essential for preserving performance and structural integrity in high-temperature applications.

Because of its strong tensile strength and resistance to impact, Nickel Alloy 201 is a dependable mechanical material for use in demanding applications. Its excellent thermal conductivity and minimal thermal expansion further improve its appropriateness for uses needing efficiency and thermal stability.

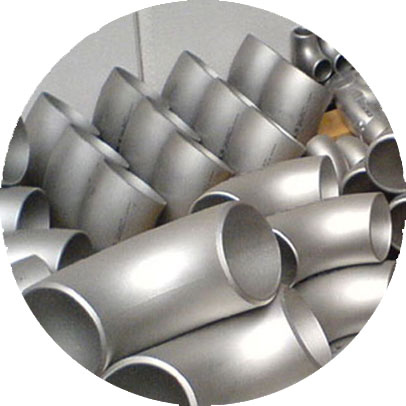

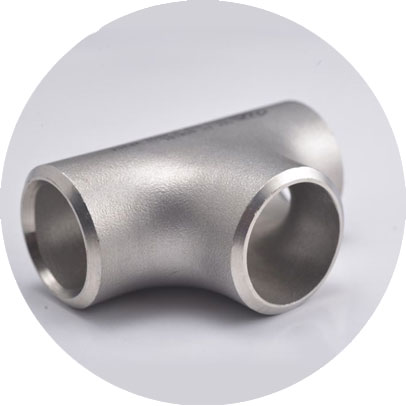

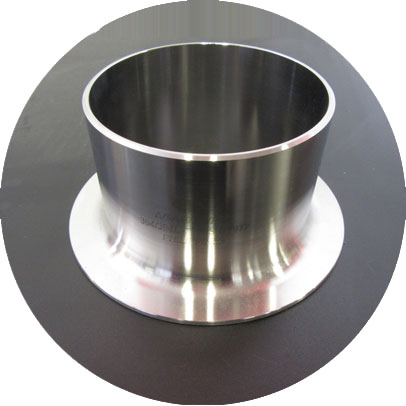

Elbows, tees, reducers, and flanges are among the parts of nickel alloy 201 pipe fittings that are necessary to build sturdy and dependable piping systems. These fittings are frequently utilized in sectors where the piping system's dependability is essential to operational success, such as oil and gas, power generating, and chemical processing.

Specification : ASTM B366 / ASME SB366

Dimension Standard : ASME/ANSI B16.9, ASME B16.28, MSS-SP-43

Size : Seamless 1/2" - 10" , Welded 1/2" - 48"

Thickness : Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS

Type : Seamless / Welded / Fabricated

Bending Radius : R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

Origin : Indian Origin, European Origin, Japanese Origin

Testing and Documents : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports

Packing : Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests

A Wide Range of ASTM B366 Nickel Alloy 201 Pipe Fittings at Best Price.

Call : +91-9820814560 or Send Enquiry

Nickel Alloy 201 Pipe Elbow

Nickel Alloy 201 Concentric Reducer

Nickel Alloy 201 Eccentric Reducer

Nickel Alloy 201 Equal Tee

Nickel Alloy 201 Cross

Nickel Alloy 201 Pipe Cap

Nickel Alloy 201 Pipe Bend

Nickel Alloy 201 Stub End

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Nickel 201 | 2.4068 | N02201 | NW 2201 | NA 11 | НП-2 | - | Ni 99.2 |

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Nickel 201 | 0.2 max max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Nickel 201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

Nickel Alloy 201 Pipe Fittings

Nickel Alloy 201 Pipe Elbow

Nickel Alloy 201 90degree Elbow

ASTM B366 Nickel 201 Equal Tee

201 Nickel Alloy Cross

Nickel Alloy ASTM B366 201 45 deg. Elbow

Nickel Alloy 201 Reducer

Alloy 201 End Pipe Cap Stockist

Alloy 201 Concentric Reducer Supplier

ASME SB366 201 Nickel Alloy Stub End

ASME B16.9 201 Nickel Alloy Pipe Bend

Nickel Alloy 201 Butt weld Fittings Exporter

N02201 Nickel Alloy U Bend

2.4068 Nickel Alloy Long Stub End Specification

201 Nickel Alloy Seamless Pipe Fittings

201 Nickel Alloy Welded Pipe Fittings

201 Nickel Alloy Eccentric Reducer

ASTM B366 Grade 201 Nickel LR ELbow Manufacturer

Fabricated Nickel Alloy 201 SR Elbow Distributor

Nickel Alloy 201 Pipe Nipple

Nickel Alloy 201 Buttweld Fittings Price

ASTM B366 201 Nickel Alloy 180 deg. Bend

Nickel Alloy UNS N02201 Butt weld Elbow

Nickel Alloy DIN 2.4068 Pipe Fittings

201 Nickel Alloy Reducing Tee

Nickel Alloy 201 Reducing Elbow

201 Alloy Butt weld Pipe Fittings Dealer

201 Nickel Alloy Buttweld Fittings

We have regular exports of Nickel Alloy 201 Butt weld Fittings in Europe, Kuwait, Bangladesh, UAE, Hong Kong, Poland, Bahrain, Jordan, Nepal, United States, Algeria, Yemen, Spain, Qatar, Ghana, Malaysia, Philippines, United Kingdom, Chile, Azerbaijan, Lithuania, Saudi Arabia, Iran, Trinidad & Tobago,Tunisia, Turkey, Brazil, Iran, Poland, Japan, France, USA, Belgium, Thailand, Estonia, Brazil, Vietnam, China, Chile, Costa Rica, Iran, Japan, Malaysia, Congo, Germany, Egypt, Tibet, United Arab Emirates, South Africa, South Korea, Ireland, Finland, Italy, Taiwan, Sweden, Czech Republic, Iraq, Puerto Rico, Austria, Ukraine, Mexico, Pakistan, Portugal, Netherlands, Denmark, Sri Lanka, Gabon, Kazakhstan, Bulgaria, Angola, Bhutan, Romania, Indonesia, Ecuador, Canada, Nigeria, Singapore, Argentina, Israel, Venezuela, Nigeria, Afghanistan, Bolivia, Peru, Russia, Switzerland, Libya, Kenya, Macau, New Zealand, Lebanon, Belarus, Mongolia, Croatia, Gambia, Morocco, Slovakia, Australia, Colombia, Norway, Oman, Hungary, Mexico, India, Zimbabwe, Namibia, Serbia, Greece.

We are Leading Supplier of ASTM B366 201 Nickel Alloy Butt weld Pipe Fittings in Mumbai, Maharashtra, Gujarat, Jamshedpur, Pune, Thiruvanthapuram, Jaipur, Lucknow, Coimbatore, Imphal, Mysore, Ratlam, Delhi, Kanpur, Darjeeling, Jalandhar, Nagpur, Solapur, Kolkata, Allahabad, Dehradun, Jammu, Nashik, Srinagar, Chennai, Ahmedabad, Faridabad, Bhadravati, Chattisgarh, Durgapur, Asansol, Hospet, Bellary, Visakhapatnam, Nellore, Surat, Bangalore, Chandigarh, Ghaziabad, Jhansi, Patna, Siliguri, Hyderabad, Amritsar, Noida, Kochi, Aizawl, Guwahati, Kozhikode, Raipur, Vishakhapatnam, Jabalpur, Bhopal, Gwalior, Ludhiana, Rajahmundry, Thane, Agra, Bhubaneshwar, Gurgaon, Madurai, Rajkot, Varanasi, Bhilai, Haridwar, Meerut, Ranchi, Ahmednagar, Akola, Amravati, Aurangabad, Baramati, Beed, Bhandara, Bhiwandi, Buldhana, Chandrapur, Chimur, Dahanu, Dhule, Dindori, Erandol, Gadchiroli, Hatkanangle, Hingoli, Ichalkaranji, Jalgaon, Jalna, Karad, Khed, Yavatmal, Kolaba, Kolhapur, Kopargaon, Latur, Malegaon, Mumbai, Nagpur, Nanded, Nandurbar, Nashik, Osmanabad, Pandharpur, Parbhani, Rajapur, Ramtek, Ratnagiri, Raver, Sangli, Satara, Shirdi, Shirur, Solapur, Thane, Wardha, Washim, Andhra Pradesh, Jammu and Kashmir, Nagaland, Uttarakhand, Haryana, Lakshadweep, Arunachal Pradesh, Jharkhand, Odisha, West Bengal, Himachal Pradesh, Assam, Karnataka, Punjab, Andaman and Nicobar Islands, Puducherry, Bihar, Kerala, Rajasthan, Chandigarh, Meghalaya, Chhattisgarh, Madhya Pradesh, Sikkim, Dadar and Nagar Haveli, Mizoram, Goa, Tamil Nadu, Daman and Diu, Tripura, Manipur, Telangana, Delhi, Uttar Pradesh in India.